Best Drill Press for Metal for Big Drilling Power

Are you looking for the ultimate tool to master metalwork projects?

The best drill press for metal can be the answer!

Not all drill presses are made alike, so if you’re serious about drilling through tough materials like steel and aluminum, it pays to invest in a quality model that won’t let you down.

Our comprehensive guide examines the features of some of today’s top drill presses to help you pick out your perfect piece of machinery.

Get ready to find out what separates a workhorse from an also-ran – with expert tips on power output and speeds – as well as key safety considerations.

Let’s take a closer look at finding the best drill press for metalworking projects!

How We Choose the Best Drill Presses for Metal

There are a lot of drill presses in the tool world, and it can be hard to figure out which one is right for you.

Not all drill presses are created equal.

Some are designed for light-duty home use, while others are built for heavy-duty industrial use.

We’ve done the research for you.

After reading through thousands of reviews on Amazon and considering the most important features and specs, we’ve selected the best drill presses for metalworking whether you’re a hobbyist or a professional.

Best Compact Profile Benchtop Drill Press

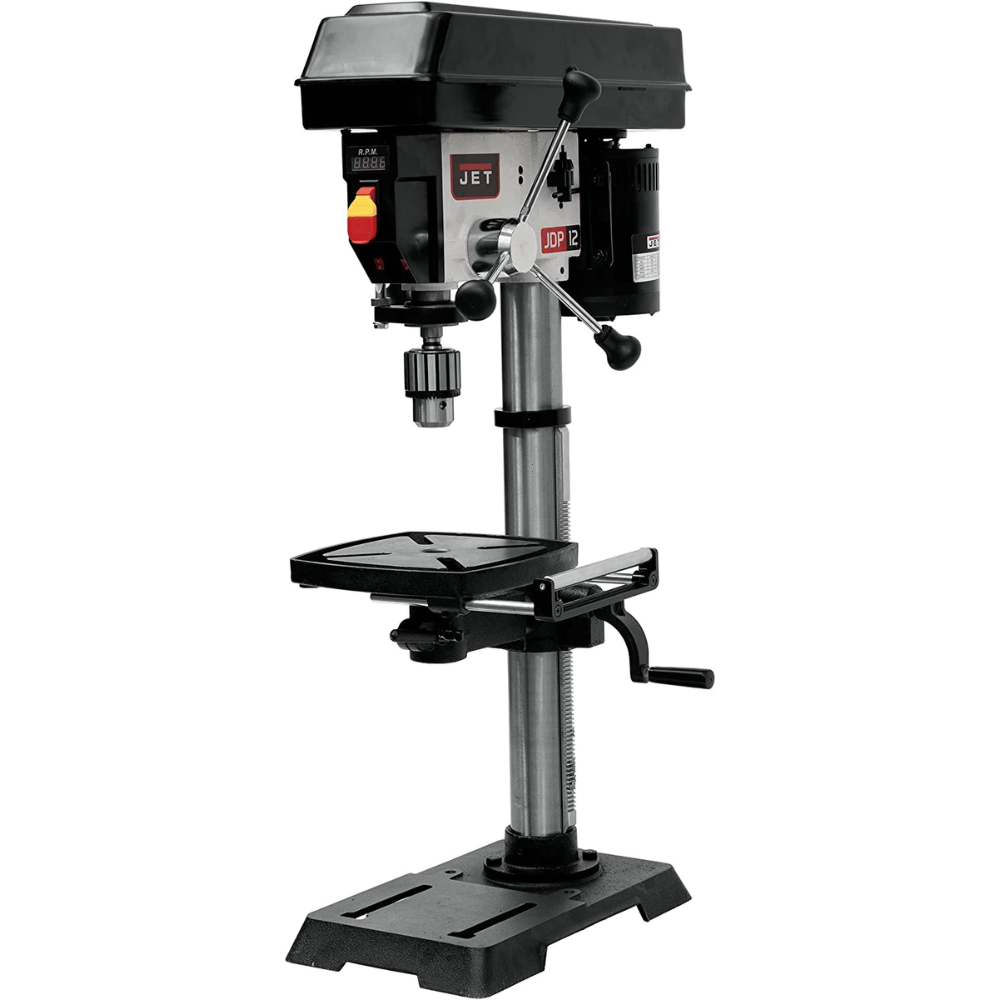

JET 12-Inch Benchtop Drill Press (JWDP-12)

Key Features

- 1/2 HP Single Phase Motor

- 12-inch swing, 5/8-inch chuck, 3-1/8-inch spindle travel

- Variable speed from 530-3,100 RPM

Why It’s a Great Choice

The JET 12-Inch Benchtop Drill Press is designed to make any project easier and more accurate.

The innovative X-shaped XACTA Laser technology will ensure accuracy on every drilling project.

The 10″ x 16-1/8″ cast iron base makes it easy to fit the drill press into even the smallest of workspaces.

With oversized, ergonomic knobs, you’ll be able to easily adjust your drill press based on the job at hand.

A LED work light helps increase visibility so that you can focus on intricate projects with precision.

The retractable roller extension provides support for larger projects and an adjustable depth stop allows for consistent drilling depths.

With all of these features rolled up into one, the JET 12-Inch Benchtop Drill Press has everything hobbyists and professionals need for their next project.

Best Metal Drill Press on a Budget

WEN 5-Amp 12-Inch Variable Speed Cast Iron Benchtop Drill Press (4214T)

Key Features

- 5 amp induction motor

- 12-inch swing, 5/8-inch chuck, 3-1/8-inch spindle travel

- Variable speed from 580-3,200 RPM

Why It’s a Great Choice

Get your job done with precision and dependability using the WEN 5-Amp 12-Inch Variable Speed Cast Iron Benchtop Drill Press.

Designed to help you accomplish any task with absolute accuracy and power, this machine is equipped with a digital speed readout that displays the current RPM of your drill.

It also features a Class IIIA 2.5mW laser so you can line things up quickly, accurately, and safely.

You’ll stay bright and focused thanks to the overhead light and adjustable depth stop as well as a table roller extension to ensure superior support while drilling.

The 9-1/2 by 9-1/2-inch work table combined with a 5/8-inch capacity keyed chuck make the WEN Cast Iron Drill Press ideal for both hobbyists and professionals alike.

Plus, a comprehensive two-year warranty provides peace of mind for any hiccups along the way.

Depend on the WEN 5 Amp 12 Inch Variable Speed Cast Iron Benchtop Drill Press to secure perfect results every time.

Best Variable Speed Floor Drill Press

Powermatic 18-Inch Floor Drill Press (PM2800B)

Key Features

- 1 HP Single Phase motor

- 18-inch swing, 5/8-inch chuck, 6-inch spindle travel

- Variable speed from 250-3,000 RPM

Why It’s a Great Choice

The Powermatic 18-Inch Floor Drill Press is an essential power tool for professionals and hobbyists alike.

The perfect blend of power and precision, this drill press is designed to get the job done in no time.

With its infinitely variable speed from 250-3000 RPM, you can switch up your speeds with no belt changes, providing you with greater control over your projects.

For added accuracy, a laser guide allows for pinpoint positioning, ensuring that your drilling remains on target.

An adjustable fence aligns your stock perfectly at a 90-degree angle to the table to ensure accurate results every time.

And it doesn’t stop there – this powerful machine also features an oversized cast iron base making it incredibly stable during operation as well as reversible handle mountings so that either side of the machine is comfortable to use.

Get ready to take control of your projects and own them like never before with the Powermatic 18-Inch Floor Drill Press!

Best Floor Drill Press for Large Stock

JET 20-Inch Floor Drill Press (JDP-20MF)

Key Features

- 1.5 HP Single Phase Motor

- 20-1/2-inch swing, 3/4-inch chuck, 4-5/8-inch spindle travel

- Variable speed from 150-4,200 RPM

Why It’s a Great Choice

Working on projects just got much easier with the JET 20-Inch Floor Drill Press.

Featuring quick adjustments, you can now make changes in a fraction of the time.

The 1/2”-diameter external depth stop has a three-nut locking feature that securely locks into place when you need it most.

With smooth operation in mind, the spindle is supported by high-quality ball bearings for less wear and tear on your machine.

Plus, an adjustable tension spindle return spring makes sure everything returns to its right place after each use.

Hobbyists and professionals alike will appreciate added visibility from the built-in work lamp that illuminates your workspace.

Making further adjustments on the press is not only simple but also fast thanks to the quick-release crank-operated worktable that can tilt 45° in either direction.

The hinged metal belt and pulley cover is coupled with a quick adjustment motor mount for changing spindle speeds whenever you need to.

Make sure to pick up your JET 20-Inch Floor Drill Press for no more fumbling around working with projects today!

Best Benchtop Drill Press that Moonlights as a Sander

Shop Fox 13-1/4″ Benchtop Oscillating Drill Press (W1668)

Key Features

- 3/4 HP Single Phase Motor

- 13-1/4-inch swing, 5/8-inch chuck, 3-1/4-inch spindle travel

- Variable speed from 250-3,050 RPM

Why It’s a Great Choice

Get a shop-quality finish with the Shop Fox 13-1/4″ Benchtop Oscillating Drill Press!

This powerful tool is perfect for hobbyists and professionals in need of an adjustable, high-precision oscillating drill press.

With a 3/4-inch drilling capacity in steel and the ability to tilt the table 90 degrees to both the left and right, users can achieve special drilling or sanding angles that are difficult with other oscillating tools on the market.

This drill also efficiently doubles as an oscillating sander for contour sanding with ease.

The adjustable table height and tilt accommodate various workpiece heights allowing users to work more precisely on a variety of projects.

Plus, you can move the table out of the way and use the base as a flat surface for your chosen project.

And with its built-in dust collection port, maintaining your workspace is made super easy.

Get reliable accuracy and smoother results while winning back valuable time with this versatile Shop Fox Drill Press – tailored to get any job done right!

Best Benchtop Drill Press for Small Projects

WEN 2.3-Amp 8-Inch 5-Speed Cast Iron Benchtop Drill Press (4208T)

Key Features

- 2.3 Amp Induction Motor

- 8-inch swing, 1/2-inch chuck, 2-inch spindle travel

- Variable speed from 740-3,140 RPM

Why It’s a Great Choice

The WEN 2.3-Amp 8-Inch 5-Speed Cast Iron Benchtop Drill Press is the perfect tool to meet your needs, no matter if you’re a novice or professional.

Featuring an impressive 6.5 by 6.5-inch adjustable worktable that bevels up to 45 degrees in each direction and depth adjustment nuts to limit your spindle travel, accurate drilling operations are made easier than ever.

At only 23 inches tall with a 7 by 11-inch base, this press will leave plenty of room for your other tools.

The 2.3-amp induction motor is designed with ball bearings for smooth balanced performance even at high speed.

And you don’t have to worry, as clamps and vises can be easily mounted on the slotted table for total versatility.

Get all your drilling and boring tasks done accurately and efficiently with the WEN 2.3-Amp 8-Inch 5 speed cast iron benchmark drill press!

Buyer’s Guide to the Best Drill Presses for Metal

You’ve decided that you want to buy a drill press for metalworking, but you’re not sure which one is right for you.

You don’t want to make a poor decision and get stuck with a huge tool you’ll never use.

We’ve compiled answers to some of the most commonly asked questions about the best drill presses for metal.

This will help you figure out which drill press is right for you and make sure that you get the most out of your purchase.

How much power do I need to make sure that my drill press can cut through metal?

Depending on the type and thickness of metal you are intending to drill through, the amount of power needed for a successful cut will vary. Generally speaking, however, a good measure of comparison is to look at the maximum horsepower that the drill press can handle. For most metals like steel, aluminum, and titanium, a minimum output of 1-2 HP is recommended to safely and effectively complete most projects.

When dealing with thicker metals such as stainless steel and cast iron, more powerful models that reach 3-5 HP may be needed to successfully create precise cuts without burning or warping the material. Ultimately, it’s best to match up your intended task with the specifications of the drill press to ensure maximum performance levels when drilling into any type of metal.

Are floor drill presses or benchtop drill presses better for metal working?

Floor-standing drill presses and benchtop drill presses both have their advantages when it comes to metalworking.

A floor-standing drill press is often more powerful than a benchtop model, making it better suited for larger projects and heavy-duty metal drilling tasks. Additionally, most floor drill presses come with a wider column and larger table, giving you more room to work with bigger pieces of metals or multiple components at once.

On the other hand, benchtop drill presses are generally lighter in weight and smaller in size, so they can be moved around easily and stored away when not in use. Additionally, benchtop units usually come with more features such as adjustable speed settings, improved depth control, better dust collection systems, etc., which makes them ideal for hobbyists or novice users who want to drill metal accurately without having to invest too much money upfront. Ultimately, it comes down to your specific needs and requirements when choosing between these two types of drill presses.

What type of maintenance do I need to do on a drill press for metal?

To ensure that your drill press is working efficiently, it’s important to regularly check and maintain the machine. This includes lubricating the parts of the drill press that come in contact with metal, such as the chuck, table surface, and spindle. It’s also important to inspect these areas for signs of wear or damage and repair any problems right away.

It’s also a good idea to inspect the wiring occasionally and make sure all connections are secure. Additionally, you should be sure to check the orientation of the on/off switch to ensure that it will not accidentally be flipped while in use. If you plan on using your drill press frequently, it’s best to invest in a dust collection system so that particles created from drilling do not accumulate inside your drill press. Finally, regular cleaning of both interior and exterior components will keep your drill press looking new and up-to-date.

What safety features should I look for in a drill press for metal?

When it comes to purchasing a drill press for metal, safety is of utmost importance. It’s important to look for models with an adjustable speed switch, as this feature allows you to adjust the rotation speed of the drill bit to match what you need for your project.

Another beneficial safety feature is a lockable chuck which will quickly and securely hold your drill bit in place and allow for fast and easy changing of bits. Additionally, look for a model with a fence or table guards to protect you from any debris that may fly up during operation. And finally, make sure there is an emergency stop button that can be used if necessary. Having all these safety features present in a drill press will greatly reduce the risk of injury while drilling into metal and ensure that your projects are completed safely and effectively.

Are there any other types of attachments that can be used with a drill press for metal?

In addition to a standard drill bit, many attachments can be used with a drill press for metal. Some of these include countersink bits which allow you to create accurate and consistent countersinks in any size holes. Besides this, you can also use annular cutters to drill holes with a smooth edge and greater accuracy than traditional twist drills. Reaming attachments are also available and make it easier to bore precisely sized and shaped holes into surfaces. Additionally, tapping attachments make it easy to thread holes without the need for extra tools. With all of these options, you have plenty of ways to get creative and tackle different projects when using your drill press for metal.

Do different size drills work better on different thicknesses of metals?

Yes, different sizes of drills work better on different thicknesses of metals. Generally speaking, larger drill bits are better suited for thicker metals, while smaller drill bits can be used on thinner materials. On very thin or soft metals, it’s best to use the smallest drill possible to avoid any damage to the surface. When working with hard metal surfaces, a larger bit is usually needed to get through the metal without breaking the bit. It’s also important to choose a bit with the right flute size for the type of metal you’re drilling into; otherwise, it can lead to uneven results and difficulty removing shavings from the hole. With all these factors taken into consideration, you’ll be able to find the perfect drill for your project and achieve great results every time.

Can I use a drill press to cut softer metals such as aluminum or brass?

Yes, you can use a drill press to cut softer metals such as aluminum or brass. The best way to do this is by using an annular cutter, which is specially designed to cut through soft metals. An annular cutter works by drilling a hole with sharp teeth on the outside rim. This allows it to quickly cut through the material and leave a smooth surface behind. Additionally, some drill presses come with tapping attachments that allow for the threading of holes into softer metals like aluminum and brass. With these attachments and the right bit size, you can easily create precise and clean cuts in any type of metal without damaging the surrounding materials.

What type of speed settings should I use when drilling into steel or other hard metals?

When drilling into steel or other hard metals, the speed settings you use should be determined by the size of the drill bit and the type of material you’re drilling into. Generally speaking, larger drill bits require slower speeds to prevent them from overheating and breaking. On the other hand, smaller drill bits require higher speeds so that they can cut through the metal quickly and effectively. It’s also important to take into account any additional factors such as material thickness or resistance, as this will affect your results. For example, some materials may require lower speed settings if they are too resistant or thick. Ultimately, by selecting a suitable speed setting for your particular job, you can ensure that your drill works efficiently and produces good results with minimal time and effort.

Is it possible to mount a vice onto a drill press for extra stability with heavy projects requiring precision drilling?

Yes, it is possible to mount a vice onto a drill press for extra stability with heavy projects requiring precision drilling. This can be done by using special mounting plates that are designed for drill presses and vices. The plates provide a solid platform for the vice to be securely attached to the drill press. This ensures that the workpiece will remain still during drilling and that any delicate or intricate drilling tasks are carried out with precision. Additionally, mounting a vice can also help to reduce vibration and noise caused by the drill press, giving you better results overall.

Choosing the Best Drill Press for Metal for You

After doing extensive research we narrowed it down to 6 great drill presses for metalworking options.

You’re now well-equipped to make a decision that works best for your needs and budget.

We hope our suggestions will help you find a product that is reliable, giving you the highest level of value for your investment.

All of these products come with features that set them apart from one another, making each one suitable for different goals.

Click the links we provided to check out prices on Amazon and order yours today so you can start exploring all that metalworking has to offer!