Best Mini Lathe for Maximum Results on a Mini Scale

Are you looking for a powerful mini lathe that delivers maximum results in minimal time and with a small investment?

Then look no further – the mini lathe is your new best friend!

The perfect tool for working with small items or generating intricate details on wood or metal projects, these benchtop machines offer incredible value when it comes to creating professional-quality designs.

Whether you’re just starting with DIY projects or are an experienced metalworker, having the right mini lathe can make all the difference between drudgery and craftsmanship.

In this article, we’ll show you how to choose which model is right for you, comparing different features so you can select one that meets your precise needs — all while keeping an eye on speed, accuracy, and cost!

Looking for something bigger? Check out our picks for the best wood lathes.

How We Choose the Best Mini Lathes

When it comes to mini lathes, there are a lot of options to choose from.

How do you know which one is the best for your shop?

You need to consider the size of the machine, the power, the speed, and more.

Do you want to spend countless hours hemming and hawing over each little detail?

We’ve done all of the hard work for you.

After reading through thousands of reviews and considering all of the important features, we’ve chosen the best mini lathes on the market.

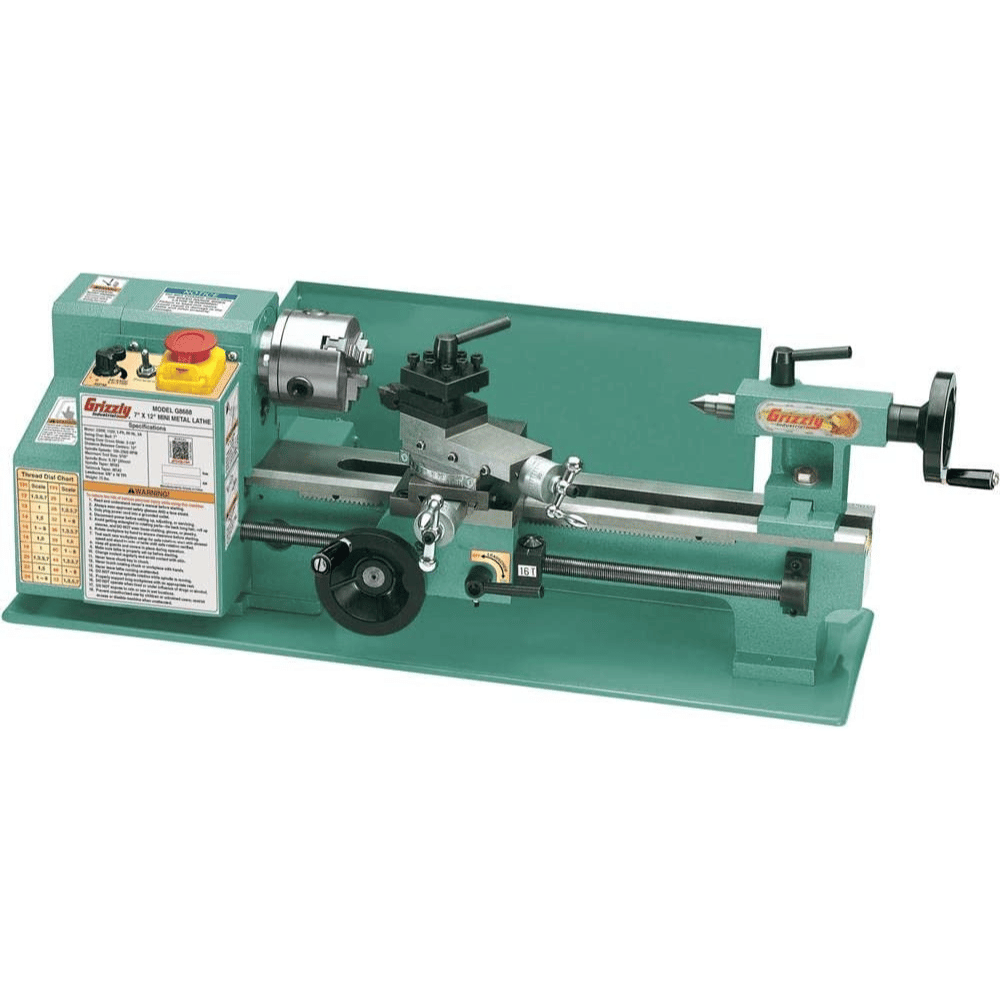

Overall Winner – Best Mini Metal Lathe Machine

Grizzly Industrial G8688-7″ x 12″ Mini Metal Lathe

Key Features

- 110V single phase 1/3 HP motor

- 12-inch distance between centers

- 7-inch swing over bed

- Variable speed control – 100-2,500 RPM

Why It’s a Great Choice

The Grizzly G8688 Mini Metal Lathe is one of the top mini metal lathes for anyone looking to have full control over their machining processes.

This lathe is powered by a 1/3 HP motor and provides you with top-notch performance, including the ability to make left-handed and right-handed threads.

It’s conveniently designed to fit on a benchtop, so it will fit in even the smallest or most crowded shops.

Plus, you’ll benefit from a variety of features such as inch and metric dials, a turret tool post, and a three-jaw chuck with external jaws.

Don’t forget about the variable-speed spindle which allows you to quickly set the speed between 0–2500 RPM!

For added convenience, the chip tray and splash guard protect against debris while it’s running forward or backward at any speed.

Make sure you have complete control over every step of your process with the help of this perfect mini metal lathe!

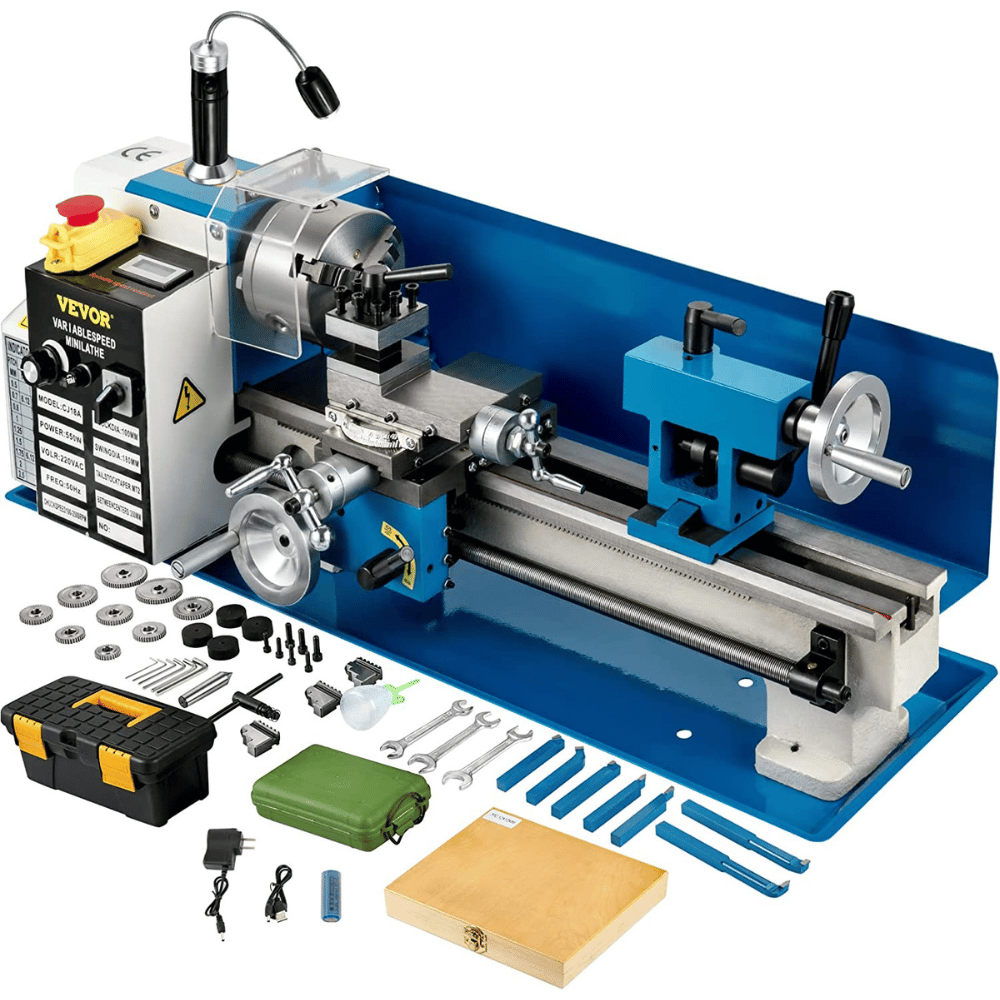

Best User-Friendly Mini Metal Lathe

VEVOR 7″x14″ Mini Metal Lathe

Key Features

- 110V single-phase motor

- 13.78-inch distance between centers

- 7.09-inch swing over bed

- Variable speed control – 50-2,500 RPM

Why It’s a Great Choice

The VEVOR 7″x14″ Benchtop Mini Metal Lathe is a great choice for DIYers and professionals.

If you’re looking to take your metalworking to the next level, then look no further!

This high-precision system requires minimal setup and offers reliable performance time and time again.

The 4-inch 3-jaw chuck easily handles square or round objects of various sizes, while LED lighting helps you work around dimly lit environments.

Underneath the hood, this power metal lathe cranks out 550W and handles small to medium projects with ease.

It also includes a 4-way quick change tool post that allows you to install four turning tools at one time without having to manually adjust each one.

Plus, speed can be monitored by the digital display for added convenience.

For those who demand precision and accuracy from their metalworking projects, there’s nothing better than the VEVOR 7″x14″ Benchtop Mini Metal Lathe!

Get started today and experience professional results every time.

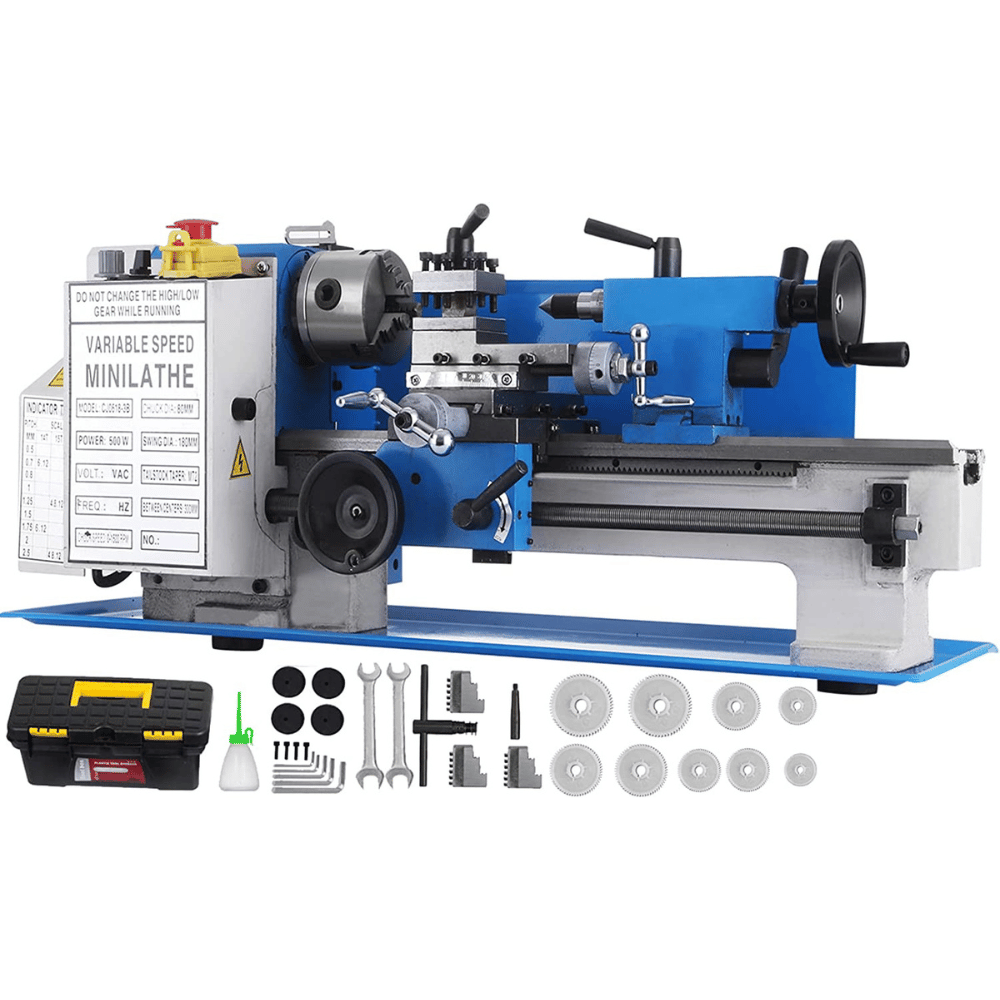

Best Precision Mini Metal Lathe

BestEquip 7″ x 14″ Mini Metal Lathe

Key Features

- 110V single-phase 3/4 HP variable speed motor

- 14-inch distance between centers

- 7-inch swing over bed

- Variable speed control – 0-2,500 RPM

Why It’s a Great Choice

The BestEquip Metal Lathe is an ideal tool for any DIYer or professional.

Its 3/4 HP motor gives you plenty of mini metal lathe power and it is packed with features that make it an easy-to-use and reliable lathe perfect for any project.

Whether you need to repair a broken bolt or design intricate mechanical parts, the BestEquip Mini Metal Lathe can handle it all!

It comes with a three-jaw chuck designed for maximum accuracy and repeatability when setting cylindrical materials.

The spindle is also supported by precision tapered roller bearings, ensuring spindle accuracy within 0.01mm.

Operate the lathe either manually or using the adjustable auto feed rate for accuracy and efficiency.

The quick change tool post allows for internal cutting, face cutting, and bevel cutting by changing both the tool post angle and adjusting the compound rest, giving you complete control over your project.

Plus, this Mini Metal Lathe also includes a backsplash guard so you can stay safe while working on your projects.

For power, precision, and performance, trust in the BestEquip Metal Lathe – get it now to enjoy endless possibilities!

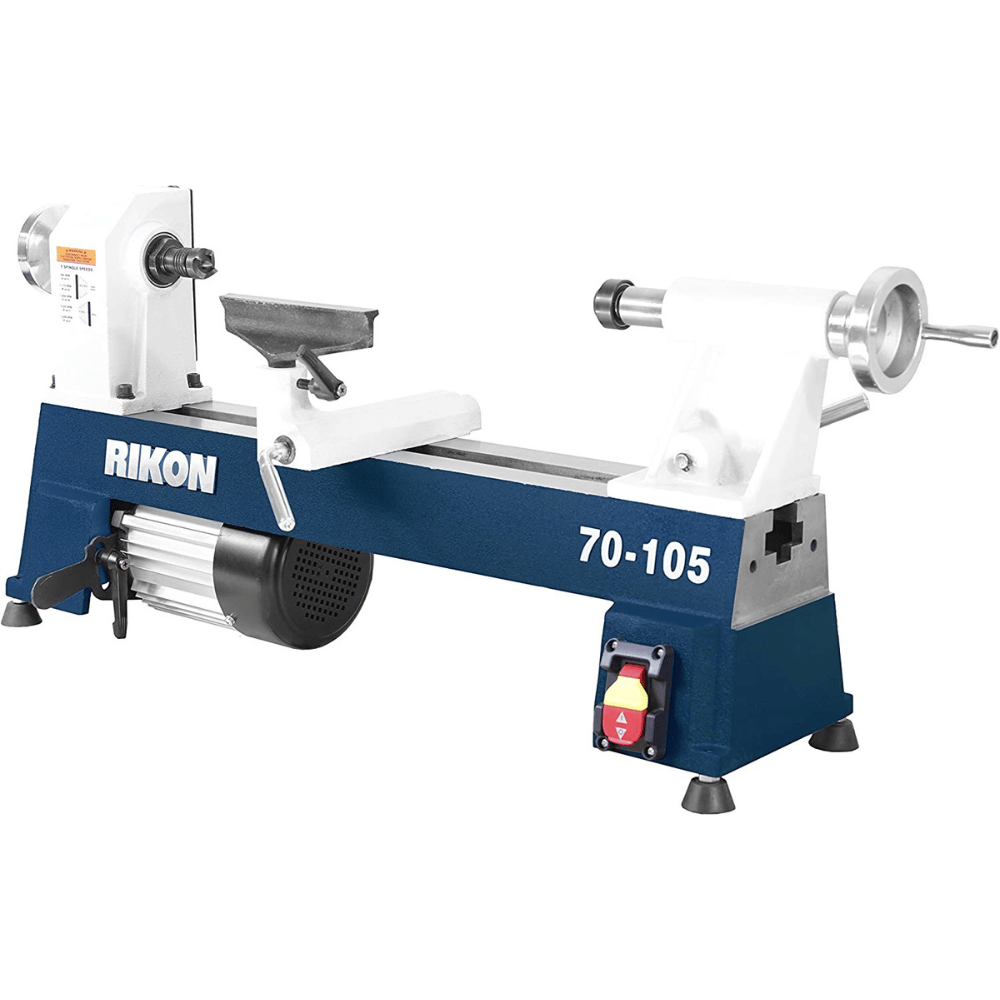

Best Mini Wood Lathe

RIKON Power Tools 70-105 10″ x 18″ 1/2 hp Mini Lathe

Key Features

- 120V single-phase 1/2 HP motor

- 18-inch distance between centers

- 10-inch swing over bed

- Variable speed control – 500-3,200 RPM

Why It’s a Great Choice

Creating beautiful, precision pieces has never been easier with RIKON’s 70-105 10″ x 18″ 1/2 hp Mini Lathe.

Specifically designed for pen turners, the top-of-the-class lathe features a heavy cast iron build to minimize vibrations while providing superior accuracy and sharpness in all cuts.

With 5 different speed ranges included in the machinery, you can effortlessly adjust your cuts and finish them off perfectly.

This state-of-the-art mini lathe is no ordinary machine – it includes a live center, tool rest, knock-out bar, and wrenches that grant users total control over their creations.

Professionals and DIYers alike can benefit from the highly compliant capabilities of this exceptional device.

RIKON’s 70-105 10″ x 18″ 1/2 hp Mini Lathe is perfect for bringing any woodworking or craftsmanship project to life with its top performance and unbeatable style.

Best Mini Wood Lathe on a Budget

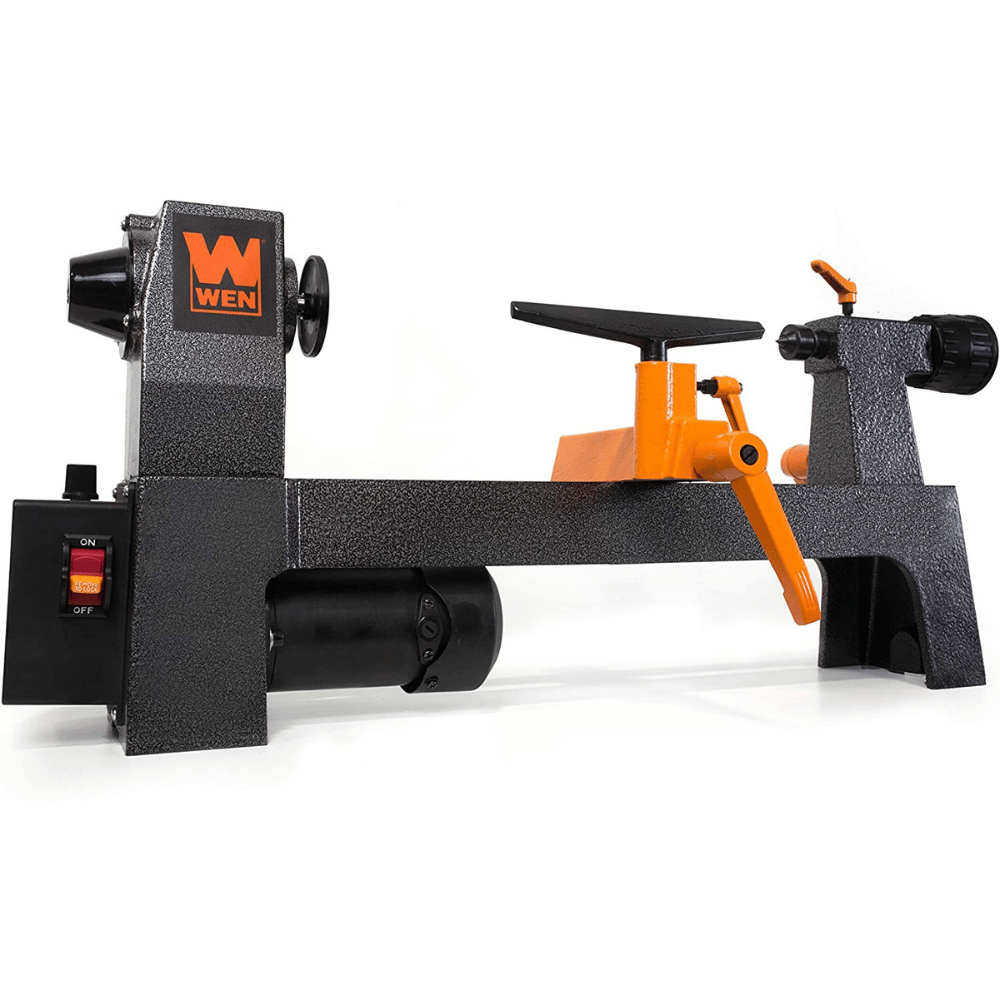

WEN LA3421 Variable Speed Mini Benchtop Wood Lathe

Key Features

- 3.2 Amp soft-start motor

- 13-inch distance between centers

- 8-inch swing over bed

- Variable speed control – 750-3,200 RPM

Why It’s a Great Choice

The WEN LA3421 Variable Speed Mini Benchtop Wood Lathe brings power and precision right to your workshop.

This mini wood lathe is equipped with a 3.2-amp soft-start motor that gradually starts up to prevent damage to the motor and maximize safety.

An MT1 spindle and tailstock taper offer a tight grip on the workpiece, making sure the piece stays securely in place for perfect results every time.

The easy-to-use lever clamping system makes quick adjustments to both the tool rest and the tailstock simple and precise, helping you save precious time on every project.

Also included are two different-sized tool rests (4-1/2 inch and 7 inches) as well as additional accessories such as a flat wrench, headstock spur center, tailstock cup center, knockout rod, and a 2.3-inch faceplate for non-spindle workpieces.

With reliable functionality and top-notch accuracy, professionals of all levels can trust the WEN LA3421 Variable Speed Mini Benchtop Wood Lathe for all their woodworking needs.

Buyer’s Guide to the Best Mini Metal Lathes

Mini lathes are a great option for small projects, but there are a lot of different options on the market and it can be hard to find the right one for you.

Not all mini lathes are created equal.

There are a lot of different features and specs to consider when choosing the best mini lathe for your needs.

We’ve put together this FAQ to help you make the best decision possible when choosing a mini lathe.

Our guide covers everything from size and power to price and portability.

What is a mini metal lathe?

A mini lathe is a specialized machine designed for use in hobby and craft markets. It is generally smaller than its full-sized counterpart, making it easier to maneuver, transport and store. Mini metal lathes provide the user with the ability to make precise cuts and shapes on wood, metal, and other materials. They can be used to create small replicas of intricate parts or objects with precision and accuracy.

Mini metal lathes have many advantages over their larger, full-size counterparts. They are generally more affordable for those on a budget and easier to set up without needing assistance from professionals who specialize in machine tool setup. The size of the mini lathe also makes it easier to use indoors in tight spaces which may not be conducive to using a full-size machine.

Because of their affordability and ease of use, mini metal lathes have become extremely popular among DIYers, hobbyists, model makers, and professional machinists alike. Quality can vary depending on the manufacturer so shopping around for one that fits your needs will ensure you receive the best product possible for your hard-earned money.

What are the benefits of having a mini metal lathe?

There are many benefits to having a mini lathe, making it an attractive option for both professional machinists and hobbyists alike.

Mini metal lathes are more affordable than their full-size counterparts, making them accessible for those on a budget. They also require less space in terms of storage, transport, and setup. This makes them ideal for those who may not have the room or resources necessary for larger models.

Mini metal lathes can provide precision accuracy when cutting and shaping materials such as wood, metal, and other materials. This allows users to make accurate replicas of intricate parts or objects with ease. Additionally, their smaller size makes them easier to maneuver and use indoors in tight spaces which may not be suitable for larger machines.

Overall, mini metal lathes offer numerous advantages when compared to large-scale options- affordability, convenience, precision accuracy, and portability being some of the most beneficial features they bring to the table.

What tasks can I do with a mini metal lathe?

A mini metal lathe is a great tool for performing various tasks and projects involving metal. From creating complex shapes to mini precision parts processing, a mini metal lathe is an invaluable asset to any machinist or hobbyist. Here are some of the tasks that can be completed with a mini metal lathe:

- Cutting: A mini metal lathe can make precise cuts on rods, tubes, screws, and other materials made of metal.

- Shaping: With a mini lathe, you can create shapes such as cylinders, cones, and squares with ease.

- Threading: You can also use a mini lathe to thread nuts, bolts, and other small pieces of hardware quickly and accurately.

- Sanding and polishing: With this type of machine, you can sand down surfaces from rough edges to smooth surfaces in no time at all. You can even add shine by polishing it to perfection.

- Reverse engineering: Small parts or objects can easily be replicated for reverse engineering purposes with a mini metal lathe.

Overall, whether you’re working on DIY projects or professional machining jobs in industrial applications, the versatility and accuracy of the mini metal lathe make it an invaluable tool for accomplishing various tasks that involve metals.

How much power do I need to turn metal on a mini lathe?

The amount of power needed to turn metal on a mini lathe will depend on several factors such as the size of your materials and the type of machining job you’re performing. Generally speaking, most mini metal lathes require between 0.5-2 horsepower per hour to operate properly.

When working with larger pieces of material or more intricate machining tasks, it is recommended that you opt for a mini lathe with a higher horsepower rating. This will help ensure that your project will be completed accurately and efficiently. Additionally, it is important to consider the torque rating of your machine as well – this will help determine not just the speed but also the stability at which your mini lathe can turn metal.

Ultimately, it is wise to research different models and find one that is suitable for your needs before purchasing a mini lathe. Doing so will make sure that you are investing in a quality machine that has enough power to complete whatever task you have in mind.

How accurate are the results of using a mini metal lathe?

The level of accuracy you can expect to get from a mini metal lathe will largely depend on the quality of the machine and how well it is operated. Generally speaking, most mini metal lathes can produce very precise results with enough practice. For example, some mini metal lathes are capable of producing parts that have dimensions within 0.001 inches or less.

The accuracy of a mini metal lathe also depends on other factors such as the cutting tools used and the type of job being done. To maximize accuracy, it is important to use high-quality cutting tools and maintain proper alignment throughout your project. Additionally, understanding techniques such as tapping and threading as well as following safety protocols can help ensure precision in results.

Overall, while the accuracy you get from a mini metal lathe may vary depending on several factors, they are generally quite accurate with enough experience and proper maintenance.

Are there any restrictions on what type of metals can be used with a mini metal lathe?

Most mini metal lathes are designed to work with a variety of metals, from softer metals such as aluminum and brass to harder materials like stainless steel or titanium. However, it is important to research the specifications of your specific model before attempting to use any type of metal with it.

In general, you should avoid using harder materials on an entry-level mini metal lathe as they may put unnecessary strain on the motor and damage the machine over time. Additionally, some machines may not be able to handle certain alloys due to their composition. Therefore, it is wise to consult the manual of your machine or reach out to the manufacturer for advice before working with a particular metal.

Ultimately, while most mini metal lathes will accommodate a variety of metals, you must understand the limitations of your machine when selecting available materials for your projects.

Are there any special safety considerations when using a mini metal lathe?

Whenever you’re using a mini metal lathe, safety should be your top priority. A few key considerations to keep in mind include:

- Wearing closed-toe shoes, safety glasses, and protective clothing.

- Being mindful of loud noise from the machine

- Making sure that any rotating parts are clear before turning on the lathe.

- Keeping your fingers away from moving parts when operating the lathe.

- Making sure all tools and guards are securely fastened before use.

- Keeping hands and feet away from the cutting area at all times.

By following these guidelines, you can help ensure a safe working environment while operating a mini metal lathe. Additionally, it is also important to stay informed about all applicable laws and regulations regarding health and safety when it comes to operating a machine like this.

What type of wood should I use on a mini lathe?

The type of wood you use on a mini metal lathe will depend on the size and purpose of your project. For smaller items, such as jewelry or decorations, softwoods like pine and balsa are typically recommended due to their flexibility and ease of turning. Hardwoods like maple and walnut can also be used for more detailed projects but may require a higher level of skill.

No matter which type of wood you use, it’s important to keep in mind that all pieces should be dry and free from any cracks or knots before beginning work on the lathe. Additionally, it is best practice to read up on the specific techniques required for each type of wood to ensure proper cutting and shaping.

Is it possible to make complex shapes on a mini lathe?

Yes, it is possible to make complex shapes on a mini metal lathe! With the right skill and experience, you can create intricate shapes such as twists, curves and flutes on the lathe. However, it is important to note that due to their size and design, mini lathes are typically not well-suited for producing larger or more intricate shapes.

If you want to make complex shapes on a mini lathe, here are a few tips to keep in mind:

- Use finely sharpened tools so that material can be cut away quickly and efficiently.

- Pay attention to the speed of the cutting – too slow could result in an uneven finish while too fast could cause wood to tear.

- Use steady hands when turning and avoid sudden movements which can lead to errors in shape or dimensions.

- Practice makes perfect – start with simple projects first before attempting more complex ones!

Are there any limitations to using a mini lathe?

Yes, there are several limitations to using a mini lathe, the most notable of which relate to the size and power of the machine. As a result of their smaller size, mini lathes generally have shorter bed lengths and limited spindle speeds, making it difficult to complete certain types of machining operations such as facing or threading. Additionally, due to their small motor size and lack of features, mini lathes typically cannot produce fine finishes on materials such as steel.

It is important to note that although mini lathes may have certain limitations when compared to larger versions, they are still capable of producing excellent results for many projects when used properly. With patience and practice, you can use your mini lathe to create beautiful pieces with high accuracy and detail.

Is there an ideal speed setting for using the mini-lathe?

The ideal speed setting for using a mini lathe depends on the project you are working on and the material you are using. Generally, when turning softer materials such as wood or plastic, higher speeds should be used. This is because soft materials can be easily cut away at faster speeds, resulting in a smoother finish.

On the other hand, harder materials such as steel require slower speeds to produce an even finish. Slower speeds also help to reduce heat build-up which can distort the workpiece.

The key to finding the right speed setting is practice – it may take some time before you find a setting that works best for your projects and materials. Once you have established what works best for each material, you’ll be able to produce consistent results every time!

How often should I replace tools and blades for my mini-lathe project?

The frequency of tool and blade replacements for your mini-lathe projects depends on the nature of the projects you are working on and the type of materials you are using. Generally, softer materials such as wood require more frequent replacement of tools and blades due to their tendency to wear out faster. Conversely, harder materials such as steel do not need to be replaced as often.

It is important to keep track of the condition and sharpness of your tools and blades, as they directly affect the quality of your finish. If you notice any dulling or chipping in your cutting edges, it’s time to replace them with a fresh set. Additionally, regular cleaning and maintenance can help prolong the life of your tools and ensure consistent results for all your projects!

Choosing the Best Mini Lathe for You

When deciding on the right mini lathe for you, consider the five great options we’ve reviewed here.

Each of these machines offers impressive features and outstanding performance in a compact design.

Whether you’re a beginner or a seasoned pro, there’s something for everyone. So what are you waiting for? Click the links to check the lathe prices on Amazon now! Order yours today and get started with your next creative project!