What Is an Impact Wrench? A Deep Dive

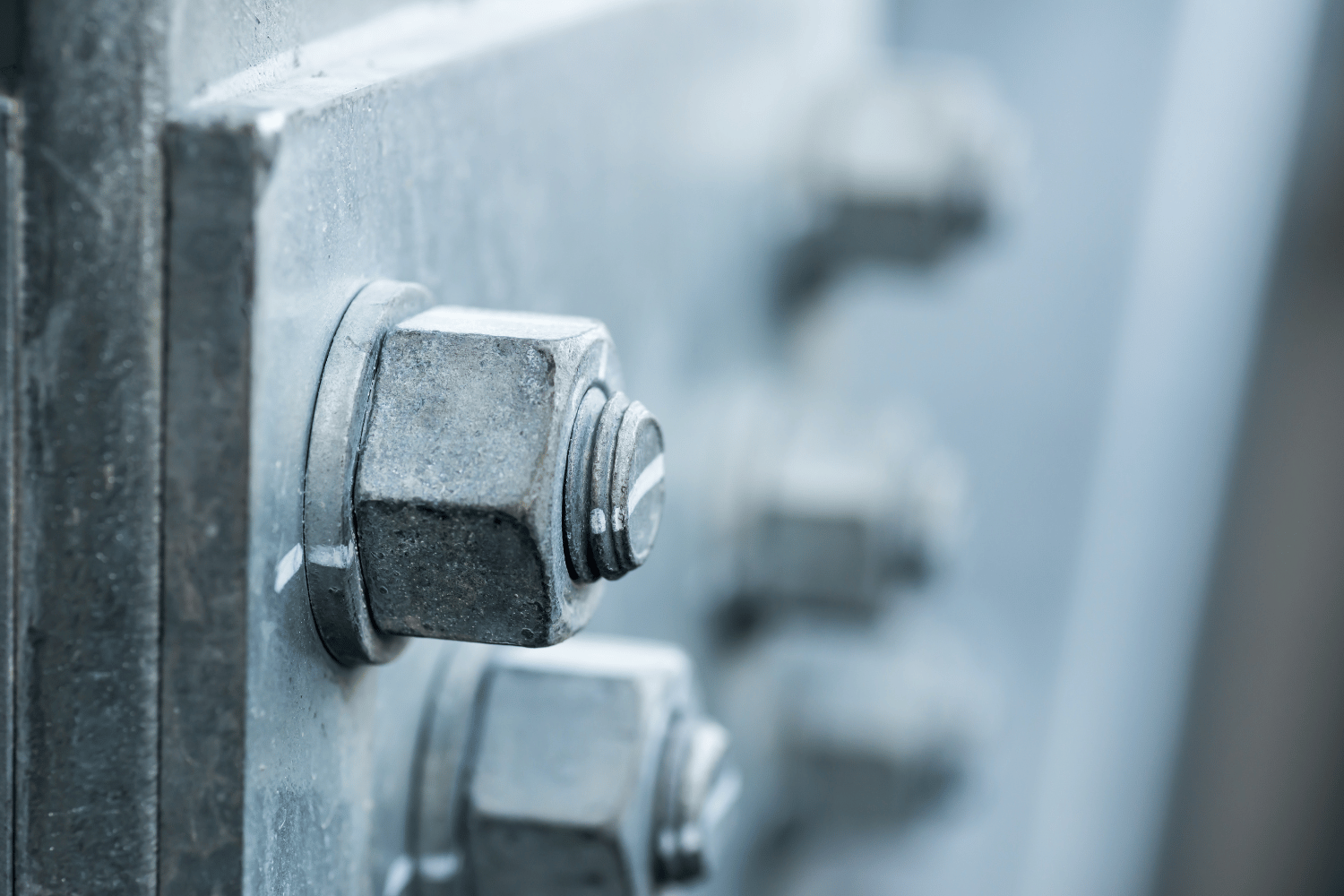

Picture this: You’re in your garage, elbow-deep in a DIY project, struggling to loosen a stubborn bolt. Frustration builds as you exert all your strength, but it refuses to budge. Suddenly, a friend appears with a mysterious tool in hand. With a swift motion, they effortlessly break the bolt free, leaving you in awe. What sorcery is this? Well, my friend, that magical tool is none other than the impact wrench.

Whether you’re an automotive enthusiast, a construction professional, or simply a handy homeowner, impact wrenches play a vital role in making your projects a breeze. These powerful tools have become indispensable in industries like automotive, construction, and manufacturing, where speed and efficiency are paramount. However, their usefulness isn’t limited to the pros alone. Even DIY enthusiasts can benefit greatly from the remarkable capabilities of an impact wrench.

In this article, we’ll dive deep into the world of impact wrenches, unraveling their inner workings, exploring the different types available, and examining their wide-ranging applications. By the end, you’ll have a clear understanding of what impact wrenches are, how they can enhance your projects, and why they have become an essential tool for professionals and DIYers alike. So, let’s embark on this enlightening journey and discover the true power of impact wrenches!

Understanding the Basics of Impact Wrenches

Definition of an impact wrench

At its core, an impact wrench is a high-powered tool designed to deliver bursts of rotational force, or torque, to tighten or loosen fasteners with ease. Its remarkable ability to generate immense power sets it apart from traditional wrenches and other power tools.

How impact wrenches differ from traditional wrenches and other power tools

Unlike traditional wrenches that rely solely on human strength, impact wrenches harness the power of automation. They eliminate the need for excessive physical effort by delivering rapid, repeated impacts that break loose even the most stubborn nuts and bolts. This efficiency not only saves time but also prevents user fatigue.

Moreover, impact wrenches outshine other power tools like drills or ratchets due to their specialized mechanism. While drills focus on rotational speed and ratchets provide continuous torque, impact wrenches combine the best of both worlds by delivering high torque output combined with rapid rotational speed.

Impact driver vs impact wrench

In terms of power, impact wrenches generally provide higher torque output and more power than impact drivers. This is necessary for handling heavy-duty applications that require significant force. Impact drivers, on the other hand, are geared towards precision and control, making them ideal for delicate tasks where over-tightening could be a concern.

Another difference lies in the overall size and weight of the tools. Impact wrenches are typically larger and heavier due to their intended applications in heavy industries and construction sites. Impact drivers are usually more compact and lightweight, allowing for greater maneuverability in tight spaces or overhead work.

It’s important to note that while impact wrenches and impact drivers share similar mechanisms involving striking and rotational force, their designs and intended uses differ. Understanding these differences helps you choose the right tool for the specific task at hand, whether it requires the brute strength of an impact wrench or the finesse of an impact driver.

Overview of the main components and mechanism of an impact wrench

To understand how impact wrenches achieve their impressive performance, let’s take a peek under the hood. These mighty tools consist of three main components: the motor, the anvil, and the hammer mechanism.

The motor serves as the powerhouse, driving the rotational force. Connected to the motor is the anvil, a square-shaped drive socket where different types of sockets or extensions can be attached. This is the part that directly engages with the fasteners.

The magic happens within the hammer mechanism. It consists of a hammer, a cage, and an anvil. When the motor rotates, the hammer spins with it inside the cage. As the hammer reaches the peak of its rotation, it gets caught in the cage, creating a sudden high-torque impact. This impact is transferred to the anvil, which then delivers the force to the fastener.

Importance of torque and rotational speed in impact wrenches

Torque and rotational speed are the dynamic duo that gives impact wrenches their awe-inspiring power. Torque determines the force applied to the fastener, while rotational speed influences how quickly the fastener can be tightened or loosened. The combination of high torque and rapid rotational speed enables impact wrenches to effortlessly handle tasks that would otherwise require considerable time and effort.

By understanding the significance of torque and rotational speed, you can make informed decisions when selecting the right impact wrench for your specific needs. Remember, high torque impact wrenches are ideal for heavy-duty applications, while adjustable rotational speeds provide versatility in tackling different projects.

Now that we’ve grasped the basics of impact wrenches and how they differ from traditional tools, let’s explore the various types available and uncover their specific applications.

Types of Impact Wrenches

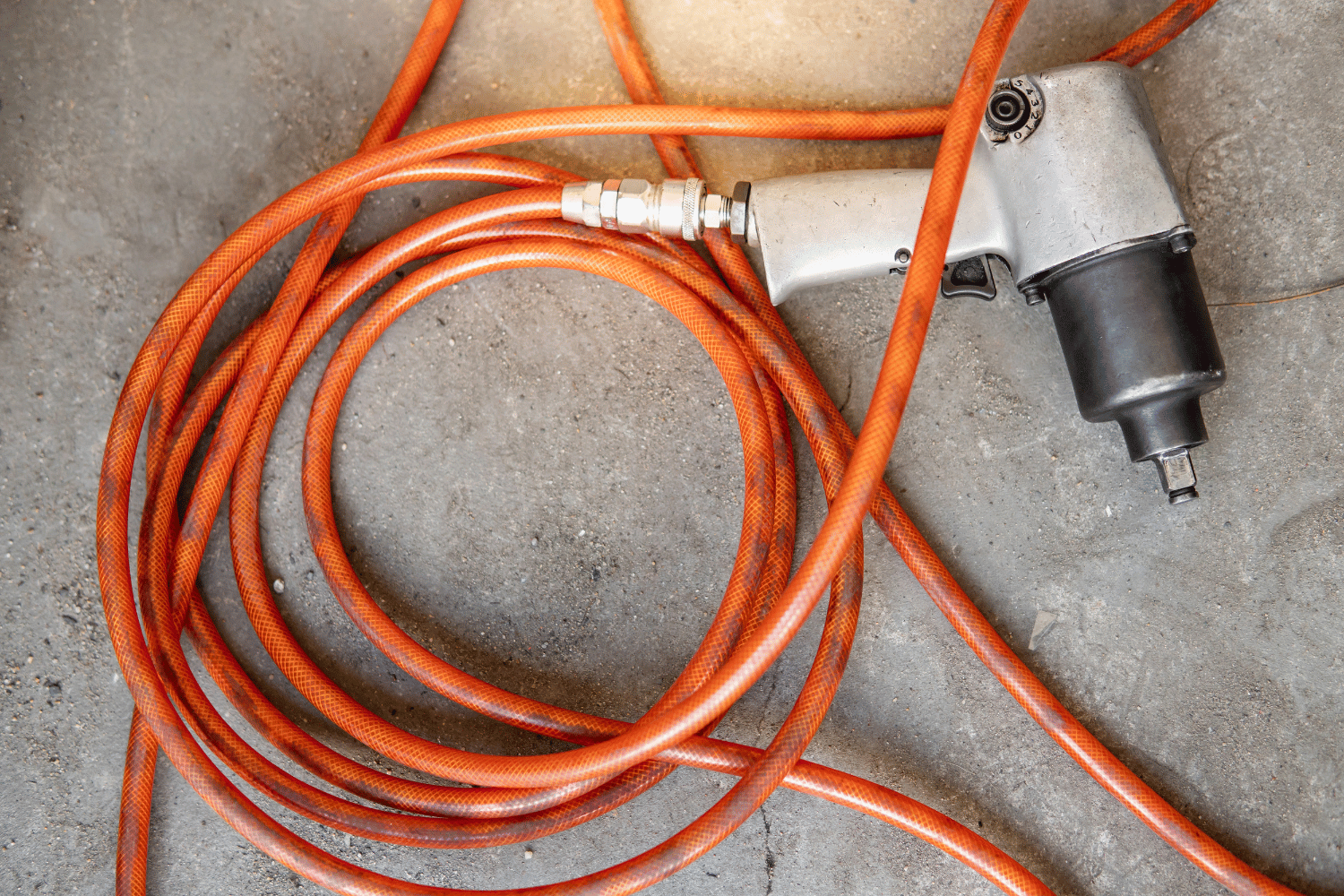

Pneumatic or Air-powered Impact Wrenches

How air-powered impact wrenches work

Pneumatic or air impact wrenches are popular in professional settings and heavy-duty applications. They operate by harnessing the power of compressed air. When you connect an air hose to the tool and supply it with compressed air, the air flows into the wrench, reaching a chamber where it drives a rotor. The rotor spins rapidly, generating the necessary torque to tighten or loosen fasteners with ease.

Pros and cons of using air-powered impact wrenches

One of the significant advantages of pneumatic impact wrenches is their high power-to-weight ratio. They are lightweight yet capable of delivering exceptional torque, making them ideal for tasks requiring substantial force. Additionally, since they don’t rely on batteries or electricity, they provide consistent power throughout the operation.

However, air impact wrenches do require an air compressor to function. This means that portability can be limited, as you need a stable supply of compressed air. They also tend to be bulkier due to the air motor, and the noise generated by the compressor can be a factor to consider.

Electric Impact Wrenches

Explanation of how electric impact wrenches work

Electric impact wrenches are known for their convenience and versatility. They are powered by electricity and feature an electric motor that drives the rotational force. The motor transfers power to a striking mechanism, similar to other impact wrenches, to generate the necessary torque for fastening or loosening tasks.

Pros and cons of using electric impact wrenches

Electric impact wrenches offer the advantage of being more portable and easier to use compared to their pneumatic counterparts. They don’t require an air compressor, allowing you to use them in various locations without worrying about air supply. Additionally, electric impact wrenches are generally more compact and produce less noise.

On the downside, electric impact wrenches may have lower torque compared to air-powered ones. However, advancements in technology have led to the development of higher torque electric models that can handle a wide range of applications. They also require a power source, which may limit their use in remote areas without access to electricity.

Cordless/Battery-powered Impact Wrenches

Explanation of how battery-powered impact wrenches work

Cordless or battery-powered impact wrenches provide the ultimate freedom and portability. They operate using rechargeable batteries, typically lithium-ion, which power the electric motor. The motor drives the striking mechanism, delivering the required torque to tackle fastening and loosening tasks.

Pros and cons of using battery-powered impact wrenches

Cordless impact wrenches offer unmatched convenience and mobility. They allow you to work without the constraints of cords or the need for a power outlet. With advancements in battery technology, they can deliver impressive torque comparable to pneumatic or electric models.

However, the runtime of these models are limited by battery life. Depending on the model and battery capacity, you may need to recharge or replace batteries during extended use. Additionally, cordless impact wrenches tend to be slightly heavier than electric ones due to the battery pack.

Understanding the different types of impact tools—pneumatic or air-powered, electric, and cordless—provides you with the knowledge to choose the right power tool for your specific needs. Each type has its own advantages and considerations, allowing you to select the one that suits your projects, environment, and preferences.

Factors to Consider When Choosing an Impact Wrench

When it comes to selecting the perfect impact wrench for your needs, several key factors should be taken into consideration. Let’s explore these factors to ensure you make an informed decision.

Power and Torque Requirements Based on Intended Applications

The first thing to consider is the power and torque requirements for your intended applications. Different tasks call for varying levels of torque, so it’s important to assess the magnitude of the fasteners you’ll be working with. If you frequently encounter heavy-duty projects or stubborn nuts and bolts, opting for an impact wrench with higher torque capabilities is essential. On the other hand, for lighter tasks, a model with lower torque may suffice while offering more maneuverability.

Considerations Regarding Size, Weight, and Ergonomics

The size, weight, and ergonomics of an impact wrench play a significant role in its usability and comfort during extended periods of use. A tool that feels too heavy or cumbersome may lead to fatigue and affect your overall efficiency. Consider the ergonomics of the handle, ensuring it provides a comfortable grip and allows for easy control. Additionally, evaluate the physical dimensions of the impact wrench to ensure it can access tight spaces or fit within your workspace limitations.

Impact Wrench Accessories and Compatibility

Accessories and compatibility are vital aspects to consider, as they can enhance the versatility and adaptability of your impact wrench. Check if the wrench is compatible with a wide range of sockets, extensions, and adapters. This allows you to work with different sizes and types of fasteners, from lug nuts to other hex head fasteners, expanding the tool’s usability. Additionally, explore the availability of accessory options, such as specialized sockets for specific applications or impact-rated drill bits for added functionality.

Budget Considerations and Cost-Effectiveness

Budget is an important consideration for many tool enthusiasts. Impact wrenches come in various price ranges, and it’s crucial to find the right balance between quality and affordability. Assess your needs and compare different models to determine the best value for your investment. While it’s tempting to opt for the cheapest option, keep in mind that quality and durability are essential factors for long-term satisfaction and cost-effectiveness. Consider reputable brands known for their reliable tools, and read customer reviews to gain insights into performance and durability.

By carefully considering these factors—power and torque requirements, size and ergonomics, accessory compatibility, and budget—you’ll be equipped to choose the ideal impact wrench for your projects. Remember, it’s essential to find a tool that aligns with your specific needs and preferences, enabling you to tackle tasks efficiently while enjoying the benefits of this powerful tool.

Final Thoughts

Impact wrenches hold immense value in a multitude of industries and DIY projects. From automotive repairs and construction work to manufacturing processes and home renovations, these tools excel in tasks that require significant force and efficiency. They save time and physical strain, revolutionizing the way we handle stubborn nuts, bolts, and screws.

Considering the versatility and advantages of impact wrenches, we encourage you to contemplate adding one to your tool collection. Whether you’re a professional tradesperson, a DIY enthusiast, or simply someone who enjoys taking on projects around the house, an impact wrench can be a game-changer. It provides the power and convenience to tackle a wide range of tasks with ease, making your projects more efficient and enjoyable.

In closing, we invite you to explore the world of impact wrenches further. Dive into the options outlined in some of our favorite articles and find one that will fit into your toolbox!

Rev up Your Work with the Best Corded Impact Wrench

Grab the Best 3/8 Impact Wrench and Knock Off Those Stubborn Bolts

Don’t Get Stuck Wrenching – Find the Best Cordless Impact Wrench for Changing Tires